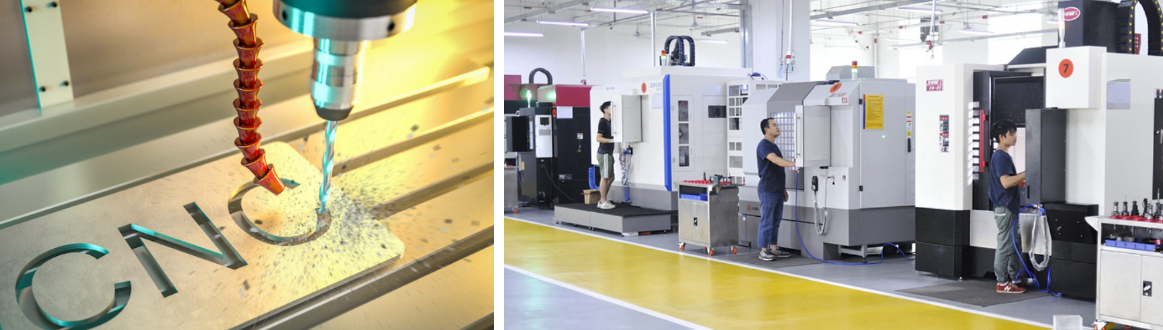

CNC precision machining

CNC means Computerized Numerical Control. It is a digitalized production process. The programming software will control the CNC machinery. CNC machinery will make product basing on programming design. CNC programming refers to changing computer-aided design of 3D CAD model to a set of machine-readable programming including cutting tools to use, the feed rate, and where to move the tool to create the final part. CNC programming is the process of creating instructions for cutting tools.

Our factory have over 100 sets of CNC machinery. We have professional R&D department. And also, R&D staff will work on client’s programming design basing on their requirement on products. We can meet all your requirements. .

CNC Features:

● Almost zero waste during production

CNC has been guided by computerized-programming. It can control raw material more accurately. Compared with man-controlled machinery, CNC can cut down waste significantly.

● less defect

With the help of CNC, it can be more precise for production. The tolerance is less than 0.02MM. It can avoid human error and traditional production process.

● cost effective

Because of less waste, it will be cost effective. All material has been controlled by computerized-programming.

Learn more about us.

Leaving message and send us 2D/3D drawings, to analyze and solve your thermal challenges

Contact us

Sitemap

Phone:+86 135 3419 4131

E-mail : riken@alvcfactory.com

ADD :Room 802A Tower A Block 3 Tian’an Cyber Park

Huangge Road Long Gang District Shen Zhen City Guang

Dong Province China.

3rd Industrial Zone Tiantou Hengli Town Dong Guang

City Guang Gong Province China.

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.