The role of fluid dynamics of Liquid Cold plate in heat dissipation

Release time:

2025-07-11 16:00

source:

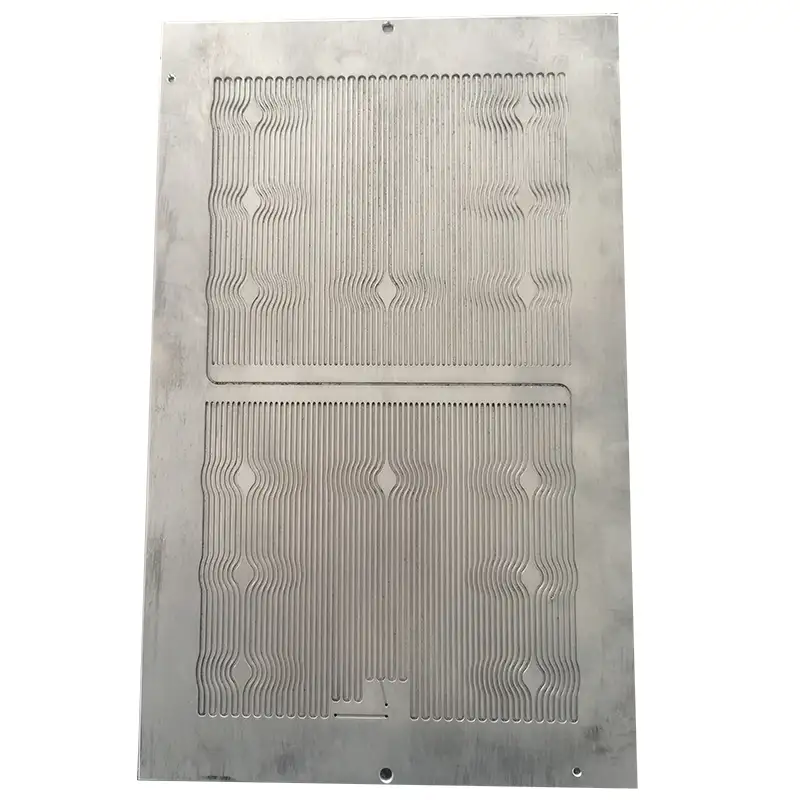

In the field of heat dissipation technology, Liquid Cold plate has attracted much attention due to its unique advantages, and fluid dynamics play an extremely important role in the heat dissipation process.

First of all, the flow rate of the fluid is a key fluid dynamics characteristic. When the coolant flows at a high flow rate in the liquid cold plate, it can quickly take away the heat. According to the principle of convective heat transfer, the increase in flow rate will enhance the convective heat transfer coefficient between the coolant and the wall of the liquid cold plate. This means that heat can be transferred from the heat source to the coolant more efficiently. For example, in the heat dissipation of high-performance computers, appropriately increasing the flow rate of the coolant in the liquid cold plate can timely transfer a large amount of heat generated by heat-generating components such as the CPU, avoiding performance degradation or equipment damage due to overheating.

Secondly, the flow state of the fluid also has a significant impact on heat dissipation. In the liquid cold plate, the fluid may present two flow states: laminar or turbulent. In the turbulent state, the particles inside the fluid mix and collide violently, which makes the temperature distribution of the coolant more uniform and is conducive to the diffusion of heat. In contrast, heat transfer in the laminar state mainly relies on molecular diffusion, which is less efficient. By reasonably designing the flow channel structure of the liquid cold plate, such as using special bends or spoiler structures, the fluid can be prompted to form turbulence, thereby improving the heat dissipation efficiency.

Furthermore, the pressure distribution of the fluid cannot be ignored. Uniform pressure distribution can ensure that the coolant flows stably in the liquid cold plate and avoid local pressure being too high or too low. If the local pressure is too low, cavitation may occur, affecting the normal flow of the coolant and the heat dissipation effect; while if the local pressure is too high, it may damage the structure of the liquid cold plate.

The fluid dynamics characteristics of the liquid cold plate play an irreplaceable role in heat dissipation. In-depth research and utilization of these characteristics can continuously optimize the design and performance of the liquid cold plate to meet the heat dissipation needs of various high-heat-generating equipment.

Blog

detail

Unveiling the Wonders of Plate Pulsating Heat Pipe Applications

Explore the fascinating applications of Plate Pulsating Heat Pipe technology in modern engineering and beyond.

The Magic of Plate Pulsating Heat Pipe: A Game Changer in Thermal Management

Explore the innovative world of Plate Pulsating Heat Pipes and their impact on thermal efficiency.

Plate Pulsating Heat Pipe: Key Considerations for Optimal Performance

Explore the essential tips and considerations for working with plate pulsating heat pipes to maximize efficiency.

Unlocking Efficiency: The Magic of Plate Pulsating Heat Pipes in Industry

Discover how plate pulsating heat pipes revolutionize thermal management across various industries.

The role of fluid dynamics of Liquid Cold plate in heat dissipation

In the field of heat dissipation technology, Liquid Cold plate has attracted much attention due to its unique advantages, and fluid dynamics play an extremely important role in the heat dissipation process.

Optimized design of Liquid Cold plate to improve heat dissipation capacity

As an efficient heat dissipation solution, Liquid Cold plate plays a key role in many high-power heat-generating devices. Optimizing its design is of great significance to improving heat dissipation capacity.